Application properties of benzyl benzoate as dyeing carrier of polyester fiber

Polyester fiber has excellent properties and wide application, but its structure is tight, crystallinity is high, and difficult to dyeing. High temperature and high-pressure dyeing temperature is not conducive to polyester/wool, polyester/ammonia blended fabric dyeing. Carrier dyeing can reduce the glass transition temperature (Tg) of polyester fiber and reduce its dyeing temperature, which has a great influence on the structure and dyeing properties of polyester fiber. Carrier dyeing of polyester fiber has attracted the attention of many dyeing and finishing workers. The carrier used in the early stage is not only toxic and heavy but also difficult to remove from the fabric, which does not meet the requirements of building an environmentally friendly and economical society.

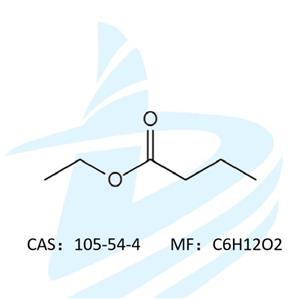

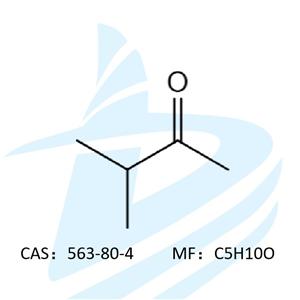

many researchers have developed environmentally friendly dyeing carriers in recent years, such as carrier dibutyl butyrate, ester carrier AB and carrier cwp -8809 can reduce the dyeing temperature of polyester fiber. although these new carriers have a good application prospect, they are still in the laboratory research stage and have not been put into industrial production.

Benzyl benzoate is a non-toxic chemical raw material with a weak almond smell. It is often used in cosmetics, food, and medicine, and meets the requirements of environmental protection dyeing carrier. By using benzyl benzoate as a carrier, the DSC curve of polyester fiber treated with benzyl benzoate was obtained by differential thermal analysis to prove its catalytic effect on polyester fiber. The breaking strength and elongation of polyester fabric treated with benzyl benzoate and benzyl benzoate were slightly higher than those treated with distilled water. It shows that benzyl benzoate will not damage the polyester fiber. The effect of benzyl benzoate on the dyeing properties of polyester fiber was analyzed, and the dyeing effect was compared with that of high temperature and high-pressure dyeing. They got a conclusion:

1) carrier benzyl benzoate has a catalytic effect on polyester fiber, and the treatment of benzyl benzoate is 51.82℃; The addition of benzyl benzoate will not damage the polyester fiber.

2) carrier benzyl benzoate can increase the dyeing rate of polyester fiber to the dispersion dye Yatron blue AQE, reduce the half dyeing time, and accelerate the dyeing balance. The dye transfer rate increases first and then decreases with the increase of carrier mass concentration.

3) The K/S value and colorfastness of fabric dyed benzyl benzoate carrier method are slightly lower than that of high temperature and high-pressure dyeing fabric, but the difference is not significant.