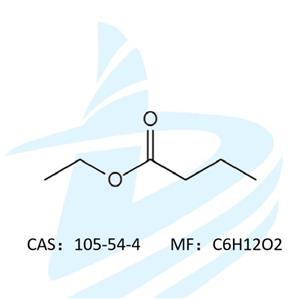

Synthesis of ethyl butyrate by butyrate fermentation broth extraction-esterification coupling

Ethyl butyrate is a colorless and transparent liquid with pineapple aroma and is widely used in flavor, food, chemistry, medicine, and energy industries. In recent years, due to the sharp fluctuation of international petroleum prices, serious environmental pollution caused by the traditional chemical industry, and the non-renewable nature of petroleum resources, biofuels, especially microbial fermentation, have attracted wide attention in the production of ethanol and butanol. besides ethanol, esters are also effective gasoline mixed additives and are expected to be substituted for fossil fuels... ethyl acetate, ethyl propionate, and ethyl butyrate are suitable fuels for homogeneous compression combustion (Homogeneouschargecompressionignition, HCCI) engines. Butyrate has similar energy value and performance to biological butanol and is superior to biological ethanol: it is basically insoluble in water and has the advantages of low steam heating and high flash point than ethanol. Butyrate can be obtained by esterification of butyric acid and alcohol produced by microbial fermentation of cheap substrate, and it is easier to produce than biological butanol. Therefore, butyrate is expected to become a new type of bioenergy. at present, a large number of studies have been carried out to produce butyric acid and ethanol by fermentation using cheap substrates (cellulose or hemicellulose biomass). a simple one-step, low-energy, and low-cost method can be established to esterify natural butyric acid and ethanol produced by fermentation under the action of natural catalyst —— lipase to synthesize ethyl butyrate to meet the current market demand for natural condiments and liquid biofuels. At present, the industrial production of ethyl butyrate is mainly by chemical synthesis, but the enzymatic synthesis of ethyl butyrate is immature. a patented method has been proposed for the production of esters —— the organic acids produced by fermentation are extracted into the extraction solvent, and then directly converted into esters with alcohols under the action of catalyst, so that fermentation, extraction, and esterification are coupled together. Finally, the organic ester is separated from the extractant by evaporation in the distillation column, so that the extraction solvent is regenerated and recycled for the extraction process. unreacted alcohols can also be collected in this process. The patent provides a large-scale production process using lipase synthetic organic esters, which makes enzymatic synthetic esters more industrial value, but no literature has reported the use of this method to produce ethyl butyrate. Among them, the yield of butyric acid was 301.0 g/L. in the study of butyric acid fermentation-extraction coupling The hollow fiber membrane was used for extraction. FBB( fiber bed bioreactor) immobilized fermentation coupling production of butyric acid, extractant Alamine336(10 V / V). oil alcohol is toxic to free cells in suspension and nontoxic to FBB immobilized cells. The key to the extraction of one esterification coupling is to select the appropriate organic solvent as the extractant and to act as the reaction solvent for the esterification reaction. The esterification reaction is carried out directly in the extraction phase to realize the coupling of the extraction. Studies have been carried out on the extraction of butyric acid fermentation broth and direct lipase-catalyzed esterification of butyric acid with ethanol in the extraction phase, The extraction of butyrate fermentation broth was realized. Esterification couple combined to form ethyl butyrate. The study shows that, Extraction agent TOA. cyclohexane can effectively extract butyric acid from the fermentation broth, It can be used to synthesize ethyl butyrate by enzymatic esterification. TOA concentration increases, The partition coefficient and extraction yield of butyrate also increased, The esterification yield of ethyl butyrate decreased; Suitable TOA concentration of 0.4 mol/L, At the time of extraction, the molar concentration ratio of TOA to butyric acid in the fermentation broth was 2:3. To optimize the key factors affecting esterification, The optimum condition is that the reaction temperature is 40, Enzyme addition L,8 The molar ratio of alkyd is 2:1, Adding 40 g, molecular sieve L. using the above optimization conditions, Novozym435 catalytic synthesis of ethyl butyrate in the extraction phase was balanced for 5 h, Moreover, the reaction 96 h has not been carried out in the direction of reverse reaction —— hydrolysis reaction; Novozym435 repeated six times in the system, The esterification rate did not decrease significantly, Maintained between 85.40% and 87.83%; 100 mL Fermented butyrate by extraction, Ethyl butyrate was 0.65 mol/mol. relative to butyrate Thus, The process of extracting ethyl butyrate from butyrate fermentation broth with one ester coupling to form ethyl butyrate has industrial application value.