VOCs organic and peculiar smell waste gas treatment technology introduction

VOCs有机及异味废气治理技术介绍

VOCs organic and peculiar smell waste gas treatment technology introduction

VOCs有机废气 VOCs organic waste gas

目前有机废气和异味废气治理技术较为复杂,通常根据行业及具体工况在确保安全和达标排 放的基础上选择最优治理工艺,在各种技术中,我公司掌握具有优势地位的几种技术如下:

At present, the treatment technology of organic waste gas and peculiar smell waste gas is relatively complex. Generally, the optimal treatment technology is selected based on the industry and specific working conditions to ensure safe and up to standard emission. Among various technologies, our company has the following advantages:

1、 氧化还原+UV/离子束技术

Redox + UV / ion beam technology

2、 氧化吸收+活性炭吸脱附+RCO技术

Oxidative absorption + activated carbon desorption + RCO technology

3、 沸石转轮+RTO/RCO技术

Zeolite wheel enrichment +RTO/CO technology

4、 高级催化氧化吸附技术

Advanced catalytic oxidation adsorption technology

5、 生物分解无害化技术

Biodegradation and harmless technology

6、临氧裂解处理复杂成分废气技术

Oxygen pyrolysis technology for treatment of complex component waste gas

VOCs工业有机废气综合解决方案

VOCs industrial organic waste gas comprehensive solution

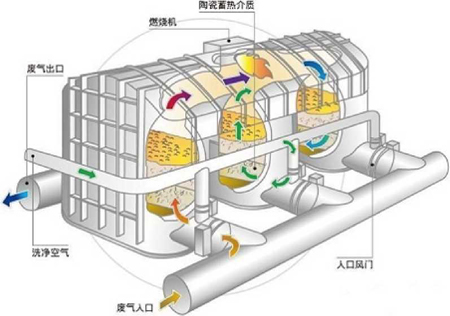

01沸石转轮浓缩+深度冷凝回收技术

Zeolite rotation concentration + deep condensation recovery technology

•转轮浓缩-冷凝回收系统是引进国际领先转轮浓缩技术,结合自主研发的废气冷凝回收技 术,开发出的一种高效溶剂回收系统。系统将吸附技术和冷凝回收技术有机结合,产品集成度高, 可将成分单一、回收价值高、大风量、中高浓度的有机废气经过吸附-脱附-冷凝过程回收高价值的 溶剂,变废为宝,实现资源再利用。

The runner concentration condensation recovery system is an efficient solvent recovery system developed by introducing the international leading runner concentration technology and combining the independently developed exhaust gas condensation recovery technology. The system combines adsorption technology and condensation recovery technology organically, with high product integration. It can recover high-value solvent from organic waste gas with single composition, high recovery value, large air volume and medium and high concentration through adsorption desorption condensation process, turn waste into treasure, and realize resource reuse

•工艺原理 Process principle

•有机废气经预处理和初步冷凝回收后,进入浓缩转轮。浓缩转轮的核心是蜂巢状转轮,为 一种特殊的吸附材一一疏水性沸石,沸石对挥发性有机物的气体有高效率的吸附能力,VOCs废气 通过转轮,沸石吸附VOCs并将干净气体排放至大气。被吸附之VOCs由脱附区利用高温脱附,脱附 的气体为高浓度低流量浓缩废气,此浓缩废气再导入冷凝系统冷凝,可回收液态溶剂。

After pretreatment and preliminary condensation recovery, the organic waste gas enters the concentration runner. The core of concentration runner is honeycomb runner, which is a special adsorption material - hydrophobic zeolite. Zeolite has high-efficiency adsorption capacity for VOC gas. VOCs waste gas is absorbed by zeolite through runner, and clean gas is discharged to the atmosphere. The adsorbed VOCs are desorbed by high temperature in the desorption area, and the desorbed gas is concentrated waste gas with high concentration and low flow rate, which is then led into the condensation system for condensation, and the liquid solvent can be recovered.

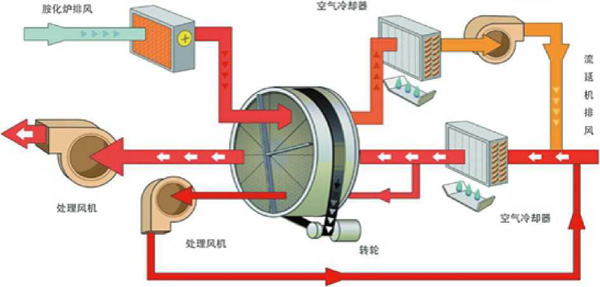

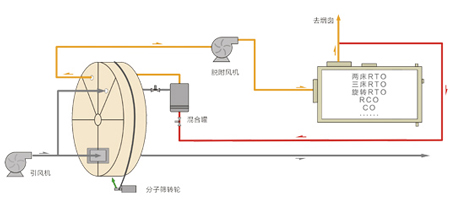

02沸石转轮浓缩+RTO/CO技术

Zeolite wheel enrichment +RTO/CO technology

沸石转轮浓缩+RTO/CO 的组合,是用于废气量较大但浓度较低的VOCs气体,首先VOCs气体会在通过浓缩转轮表面时被吸收,吸收后的气体体积会被压缩3-20倍,经过压缩后的高浓度废气排往 RTO或CO进行处理,高VOCs浓度的气体可替代燃气/燃油作为能源使用。

The combination of zeolite wheel concentration and RTO / CO is used for VOCs with large amount of waste gas but low concentration. Firstly, VOCs gas will be absorbed when passing through the surface of the concentration wheel, and the volume of the absorbed gas will be compressed 3-20 times. The compressed high concentration waste gas will be discharged to RTO or CO for treatment. The gas with high VOCs concentration can be used as energy instead of gas / fuel oil。

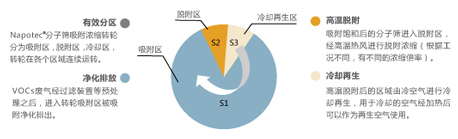

将有机废气流经蓄热陶瓷体,经加热后,温度迅速提升,在炉膛内温度可达到800度 ,有机废气中的VOCs在此高温下直接分解成二氧化碳和水蒸气,形成无毒、无味的高温烟气 。

The organic waste gas flows through the thermal ceramic body. After heating, the temperature rises rapidly. The temperature in the furnace can reach 800 degrees. The VOCs in the organic waste gas can be directly decomposed into carbon dioxide and water vapor at this high temperature, forming non-toxic and tasteless high-temperature flue gas。

混合气体流经温度稍低的蓄热陶瓷,大量热能即从烟气中转移至蓄热体,用来加热下一次循环的有机废气,高温烟气的自身温度大幅度下降,再经过热回收系统和其他介质发生热交换,烟气温度进一步降低,最后排至室外大气。

The mixed gas flows through the heat storage ceramics with a slightly lower temperature, and a large amount of heat energy is transferred from the flue gas to the heat storage body to heat the organic waste gas in the next cycle. The temperature of the high-temperature flue gas is greatly reduced, and then the heat exchange occurs through the heat recovery system and other media. The temperature of the flue gas is further reduced, and finally discharged to the outdoor atmosphere。

(1)适应行业范围:烘炉废气、化工电泳、涂装、喷漆、印刷、电子等行业的废气处理

Applicable industry scope: exhaust gas treatment in ovens, chemical electrophoresis, painting, painting, printing, electronics and other industries

(2 )适应废气浓度:500~10000mg/m3

Adapt to exhaust gas concentration: 500 ~ 10000mg / m3

RTO系统中设置了多个蓄热室,以保证每个蓄热室依次经历蓄热-放热-清扫等程序,周而复始,连续工作。蓄热室“放热”后应引入洁净空气对室内进行清扫,待清扫完成后方可进入“蓄 热”程序,否则残留的废气分子随烟囱排入大气中,从而降低了处理效率。

In RTO system, multiple regenerators are set up to ensure that each regenerator experiences heat storage, heat release, cleaning and other procedures in turn, and works continuously. Clean air should be introduced into the regenerator to clean the room after "heat release". After cleaning, the "heat storage" procedure can be entered. Otherwise, the residual exhaust gas molecules will be discharged into the atmosphere along with the chimney, thus reducing the treatment efficiency.

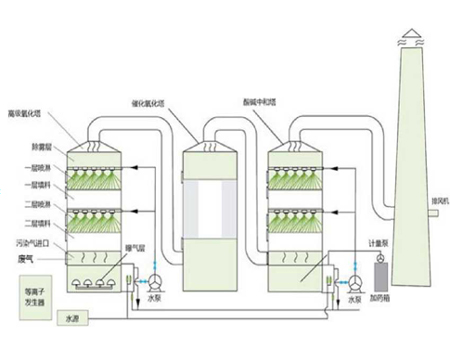

03高级催化氧化吸附技术

Advanced catalytic oxidation adsorption technology

高级氧化技术是对传统处理技术中的经典化学氧化法,在改革的基础上应运而生的一种新技术方法,高级氧化技术advanced OxidationProcesses简 称AOP。指羟基自由基(0H)使难降解的污染物氧化成CO2、H20和无害羧酸,接近完全氧化。它是最有前景的处理难降解污染物的方法。

Advanced oxidation technology is a new technological method that arises at the historic moment based on the reform of the classical chemical oxidation method in the traditional processing technology. Advanced oxidation technology is simply called AOP. Hydroxyl radicals (0H) oxidize refractory pollutants into CO2, H20, and harmless carboxylic acids, near complete oxidation. It is the most promising method for treating refractory pollutants。

利用AOP技术处理恶臭气体,羟基自由基在杀菌、消毒、除臭与有机物反应后,其最终生 成物是CO2、H20和无害羧酸。氧化催化剂为贵金属氧化物,氧化剂在催化剂的作用下,产生氧化性极强的羟基自由基(0H ),这些自由基可分解几乎所有有机物,将其所含的氢(H )和碳(C ) 氧化成水和二氧化碳。除电耗、水耗外,不消耗其他原料,不带来二次污染,无需二次处理.

Using AOP technology to treat malodorous gases, hydroxyl radicals react with organic compounds after sterilization, disinfection and deodorization, and their most lifetime components are CO2, H20 and harmless carboxylic acid. The oxidizing catalyst is a noble metal oxide. Under the action of the catalyst, the oxidant produces highly oxidizing hydroxyl radical (0H), which can decompose almost all organic matters and oxidize the hydrogen (H) and carbon (C) contained in it into water and carbon dioxide. In addition to power consumption, water consumption, no other raw materials, no secondary pollution, no secondary treatment.

04生物分解法无害化技术

Biodegradation harmless technology

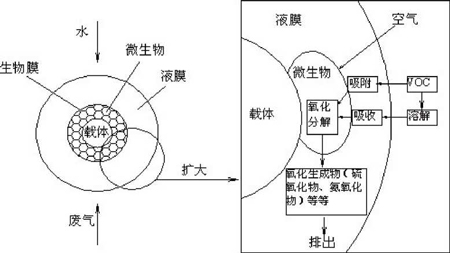

生物洗涤除臭工艺采用“微生物”降解技术,利用生长在填料上的除臭微生物对臭气中的恶臭物进行吸收和降解从而达到除臭的目的。由于微生物具有细胞个体小、表面积大、吸附性强、代谢类型多样的特点,臭气经过收集系统收集后再通充满活性微生物的滤层,利用微生物细胞对恶臭物质的吸附、吸收和降解功能,将恶臭物质吸附后分解成CO2、H2O、HNO3等简单无机物。

The biological washing and deodorization technology adopts the "microbial" degradation technology, which uses the deodorizing microorganism growing on the filler to absorb and degrade the odor in the odor, so as to achieve the purpose of deodorization. Due to the characteristics of small cell size, large surface area, strong adsorption and various metabolic types, the odor is collected by the collection system and then passed through the filter layer full of active microorganisms. The odor is absorbed and decomposed into simple inorganic substances such as CO2, H2O and HNO3 by using the adsorption, absorption and degradation functions of microbial cells for odor substances。

05临氧裂解处理复杂成分废气技术

Oxygen pyrolysis technology for treatment of complex component waste gas

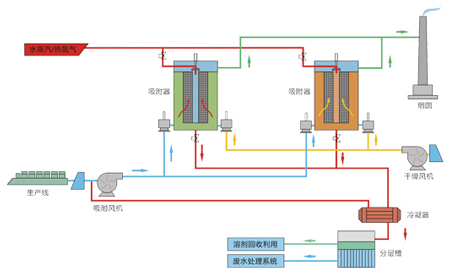

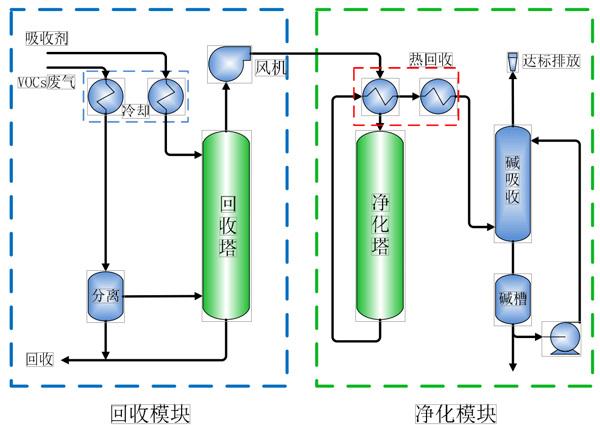

VOCs 废气种类繁多,来源广泛, VOCs 废气分为高浓度(VOCs>10000mg/立方米)和低浓度(VOCs<10000mg/立方米)两种。废气中的 VOCs 大多为生产过程所使用的原料、中间产物或产品,综合考虑 VOCs 的价值和回收成本,对于高浓度的废气 需要进行资源回收利用,低浓度的废气则可直接净化处理。针对不同浓度和种类的 VOCs废气,我们设计了回收和净化两个基本单元模块,可单独或组合使用,如下图所示

There are many types of VOCs exhaust gas and a wide range of sources. VOCs exhaust gas is divided into high concentration (VOCs> 10000mg / m3) and low concentration (VOCs <10000mg / m3). Most of the VOCs in the exhaust gas are raw materials, intermediate products or products used in the production process. Considering the value of VOCs and the cost of recycling, high-concentration exhaust gas needs to be recycled and reused. Low-concentration exhaust gas can be directly purified. For different concentrations and types of VOCs waste gas, we have designed two basic unit modules for recovery and purification, which can be used individually or in combination, as shown in the figure below.

(1) 回收模块 Recovery module

采用冷凝和吸收组合法,先将 VOCs 废气进行冷却,使部分有机物形成液滴从气体中分离出来,剩余气体再进回收塔,采用低挥发度吸收剂进行吸收。吸收剂优先选择生产工艺中所使用的原料、中间产物、产品等体系中存在的物料, 吸收所得物料可返回生产装置循环使用。回收过程采用具有特殊结构的吸收塔, 废气流量可在较大范围内波动,使用较小量的吸收剂即可达到理想的吸收效果,具有操作弹性大、回收率高的显著优点。

The combined method of condensation and absorption is used to first cool the VOCs exhaust gas so that part of the organic matter formed droplets are separated from the gas, and the remaining gas is then sent to the recovery tower for absorption with a low-volatility absorbent. The absorbent preferentially selects materials existing in the raw materials, intermediate products, products and other systems used in the production process, and the materials obtained after absorption can be returned to the production device for recycling. The recovery process adopts an absorption tower with a special structure, and the exhaust gas flow can fluctuate in a large range. The ideal absorption effect can be achieved by using a small amount of absorbent, which has the significant advantages of large operating flexibility and high recovery rate.

(2) 净化模块 Purification module

采用临氧裂解法,对 VOCs 废气进行一站式净化。将 VOCs 废气与净化后的高温 尾气进行热交换,进入净化塔后 VOCs 进行氧化反应,然后达标排放。针对不 同废气种类,还可配套碱吸收设备,用于中和吸收含氯、氮、硫、磷等 VOCs净化后产生的酸性气体

One-stop purification of VOCs exhaust gas using pro-oxygen cracking method. The VOCs exhaust gas is exchanged with the purified high-temperature exhaust gas. After entering the purification tower, the VOCs undergo an oxidation reaction, and then discharge to the standard. For different types of exhaust gas, it can also be equipped with alkali absorption equipment for neutralizing and absorbing acidic gas generated after purification of VOCs containing chlorine, nitrogen, sulfur, and phosphorus